Electrostatic Oil Cleaner (CDOC)

Electrostatic oil cleaning machine is one of the most advance technology to keep your lubrication (mineral oil) clean and long lasting. It also will help your machine free of abrasive materials and enhance the life span of your machine. Pay back period for this type of machine is at most 18 months. It can remove particles as low as 0.05 micron. This is more than 200 times more efficient than the normal filter.

This machine is widely used in power plant turbine lubrication system, injection mould equipment, rubber moulding plants, paper manufacturing plants and all types of plants which are using mineral oil for their machines.

Principle of Working

Electrostatic Oil Cleaner uses electrostatic precipitation to remove sub-micron particle of insoluble material, without effecting soluble oil additives. Tiny particles are electrostatically driven to, then captured on, the positively or negatively charged walls of electrodes. Large particles are trapped in the resin impregnated cellulose filter. Coalesce filter in dehydration cell is used for removal of moisture or water up to 5000 PPM. Modern additives treated oil is highly resistant to deterioration, it can continue service indefinitely if kept clean and free from contamination.

Benefits

- No more oil changes

- Alpha-numeric fault detection time

- No attendance required during operation

- Cleans particulate from any non-conductive fluid

- Improve performance of hydraulic components to meet high speed & precision demand

- Eliminates oil related breakdown such as pump, motor, valve failures & leakages, etc

- Eliminates oil disposal & recycling problem

- Easy to install

- Low operation cost

- Reduce power consumption

- Extremely short payback

CDOC Cleans

- Contamination up to < 0.01 μ

- Metallic contaminant

- Non Metallic contaminant

- Dust, rust

- Moisture up to 5000 PPM

- Traps contaminant occurs due to oxidation viz suspended carbon particles,

sludge, tar and varnishes. - Maintains oil quality better than new oil i.e. Nas class 5-6

Applications

- Plastic Machinery

- Construction Machinery

- Hydraulic Press

- Aviation

- Mining Machinery

- Transmission Equipments

- Machine Tools

- Automobile Industry etc.

- Power Press

- Steel Industries

- Sugar Mill

- Turbine Oil in Hydro Power Station

- Instrumentation & Refrigeration

- Earth Moving Equipment

- Aluminum / non Ferrous Extrusion Plants

- Plywood Hot Press

- Servo Value – Controlled Hydraulic System

- Leather Processing

Operation Parameter

Temperature: – below 75 ˚C

Oil Viscosity: – below 200 cst.

Moisture content: – below 5000 PPM

No water base / detergent oil.

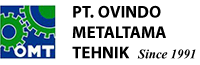

Schematic View

From The Oil Sump (Tank), the Hydraulic oil is sucked into the dehydrating cell by direct driven gear pump. Through the dehydrating cell moisture content in the oil is brought down from 5000 ppm to 500 ppm.

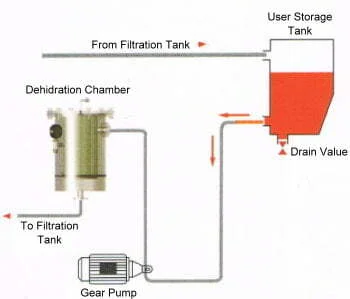

The moisture free oil is exposed to the high voltage (12 kv) with current rating of 12 mA. The contamination from the oil (burs and ferrous particles) get charged and get attracted towards the positive and negative plates. Between these plates there are collector papers (Filter papers) to absorb these contamination. Thus the ferrous particles are deposited by their charge on respective plates, the non ferrous particles like carbon are removed from the oil because of cramping of collector paper. Thus the clean oil flows from the top outlet back to the oil sump.